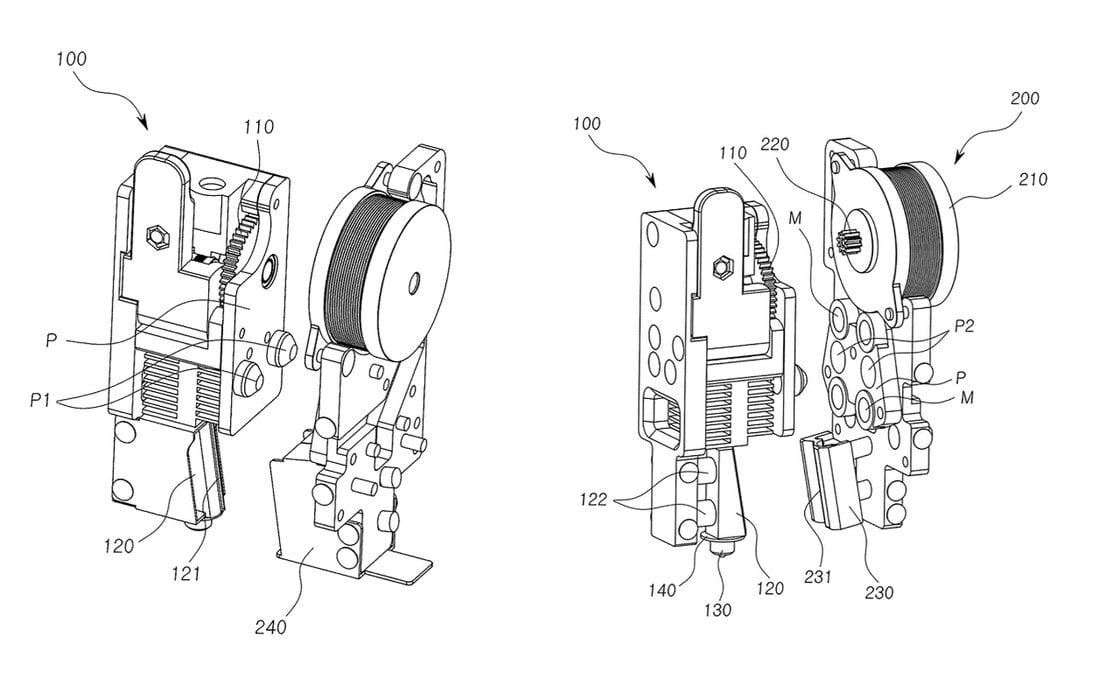

Drawings from Lugo Labs’ recent patent [Source: PatentScope]

Drawings from Lugo Labs’ recent patent [Source: PatentScope]

An interesting patent was just awarded to Lugo Labs for a hot end swapping system.

Patent W02025244395, “Multi-Output-Head Module for 3D Printer” describes a method of swapping hot ends efficiently within a FFF 3D printer. This is extremely similar to what we saw last year with the company’s H1 system.

The H1 is a professional FFF 3D printer that had the then-unique ability to print in up to six different materials simultaneously. This was enabled by a fascinating toolchanger design where the changed element is just the hot end. This meant only …

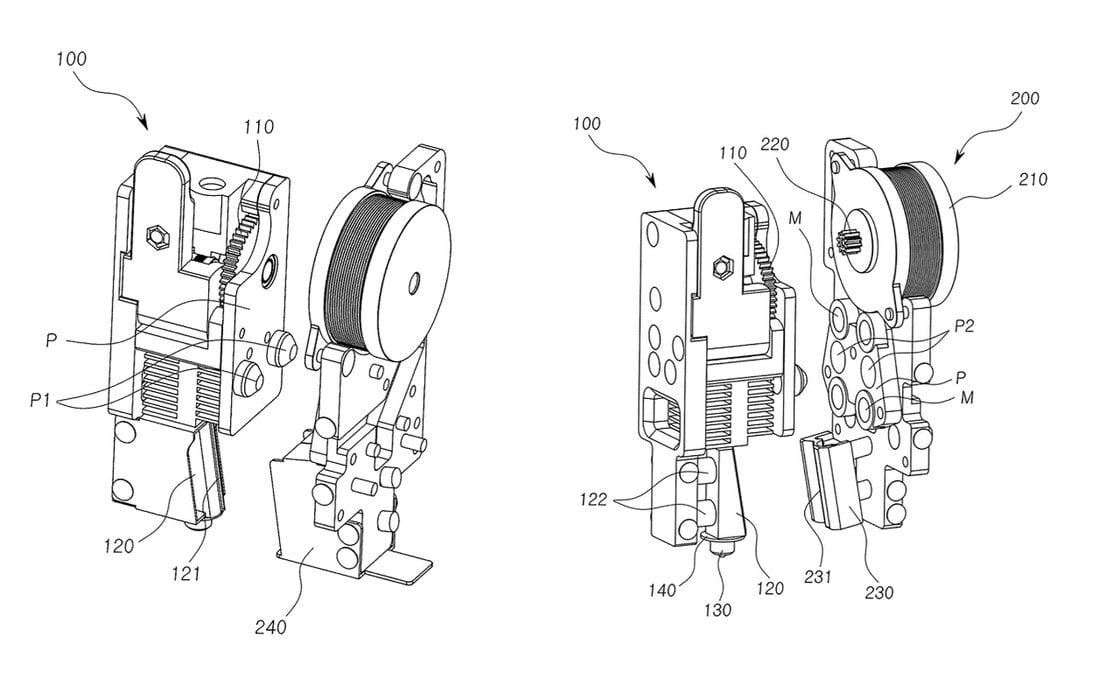

Drawings from Lugo Labs’ recent patent [Source: PatentScope]

Drawings from Lugo Labs’ recent patent [Source: PatentScope]

An interesting patent was just awarded to Lugo Labs for a hot end swapping system.

Patent W02025244395, “Multi-Output-Head Module for 3D Printer” describes a method of swapping hot ends efficiently within a FFF 3D printer. This is extremely similar to what we saw last year with the company’s H1 system.

The H1 is a professional FFF 3D printer that had the then-unique ability to print in up to six different materials simultaneously. This was enabled by a fascinating toolchanger design where the changed element is just the hot end. This meant only one extruder motor was required, as opposed to the toolchangers of the day, which had a full extruder on each tool.

Toolheads, basically hot ends, for the Lugo Labs H1 [Source: Fabbaloo]

Toolheads, basically hot ends, for the Lugo Labs H1 [Source: Fabbaloo]

Lugo Labs also made a point of explaining in detail how the tool heads are perfectly aligned when mounting, defeating calibration issues.

Now it seems they’ve been awarded a patent for this method, and it is quite timely.

Since we last saw Lugo Labs, much has happened. The FFF world has been turned upside down by an explosion of single-nozzle filament swapping machines, making multicolor 3D printing a desirable feature. However, that type of equipment also generated a distaste for filament wastage, which is massively increased with these systems.

The result has been several companies devising multicolor desktop FFF 3D printers that are low or no waste systems. Snapmaker has a toolchanger with four dedicated extruders, for example.

But the more interesting technologies are from Prusa Research/Bondtech and Bambu Lab.

Prusa Research partnered with Bondtech to install the INDX system on future Prusa devices. INDX involves dedicated hot ends that are swapped in as required during a print job.

Meanwhile, Bambu Lab introduced Vortek, a system in which specialized hot ends are dedicated to specific materials. These hot ends are swapped in as required during a print job.

Does all this sound familiar? It seems that INDX, Vortek and Lugo Lab’s patent are all doing the same thing.

They are — but doing so in slightly different ways. Vortek and INDX use induction heating, while Lugo Labs apparently does not. The method of connection between the tool and the moving mount differ significantly. In fact, the Lugo Labs patent mostly talks about this interconnection.

And all of these are patented.

It’s unlikely that we will see patent infringement cases between them, as this is likely a case of parallel evolution.

However, the important thing here is that yet another method of waste free FFF 3D printing has been patented. This takes another method off the field for any 3D printer manufacturer still seeking a similar solution.

It’s very likely that those currently without such a technology, including Creality, Anycubic, Elegoo and several others, are actively working on a solution behind the scenes.

I think they’d better hurry up.

Via Patentscope

By Kerry Stevenson

Kerry Stevenson, aka "General Fabb" has written over 8,000 stories on 3D printing at Fabbaloo since he launched the venture in 2007, with an intention to promote and grow the incredible technology of 3D printing across the world. So far, it seems to be working!

View all of Kerry Stevenson’s posts.