Charles R. Goulding and Preeti Sulibhavi consider how rammed earth, one of humanity’s oldest building techniques, is discovering new life through large-scale 3D printing and redefining what sustainable housing can look like.

For most of human history, people built with the ground beneath their feet. Earth, compacted and shaped by hand, formed walls that were durable, thermally stable, and deeply connected to local environments. Rammed earth construction is one of the clearest examples of this tradition. Today, that same idea is being reimagined with an unlikely partner: large-format 3D printers.

As additive manufacturing continues to move beyond plastics and metals, architects and builders are turning to soil-based materials to address two urgent challenges at once: the environme…

Charles R. Goulding and Preeti Sulibhavi consider how rammed earth, one of humanity’s oldest building techniques, is discovering new life through large-scale 3D printing and redefining what sustainable housing can look like.

For most of human history, people built with the ground beneath their feet. Earth, compacted and shaped by hand, formed walls that were durable, thermally stable, and deeply connected to local environments. Rammed earth construction is one of the clearest examples of this tradition. Today, that same idea is being reimagined with an unlikely partner: large-format 3D printers.

As additive manufacturing continues to move beyond plastics and metals, architects and builders are turning to soil-based materials to address two urgent challenges at once: the environmental impact of conventional construction and the need for affordable, resilient housing. The convergence of rammed earth and 3D printing is not a futuristic concept. It is already happening, and it offers a compelling glimpse into the future of eco-friendly architecture.

Understanding Rammed Earth Construction

Rammed earth is a building technique that involves compressing a damp mixture of soil, sand, gravel, and sometimes a stabilizer like lime or cement into formwork. The material is packed in layers, or “rams,” until it becomes a dense, stone-like wall. Once cured, rammed earth structures are known for their strength, fire resistance, and longevity.

Architects have long valued rammed earth for its low embodied energy. Unlike concrete, which requires energy-intensive cement production, rammed earth can often be made from locally sourced soil. This reduces transportation emissions and ties the building directly to its landscape.

According to Earth Architecture, properly constructed rammed earth buildings can last for centuries with minimal maintenance, while offering excellent thermal mass that helps regulate indoor temperatures naturally. These qualities make rammed earth especially attractive in regions facing rising energy costs and extreme weather patterns.

Why Add 3D Printing to the Equation?

Traditional rammed earth construction is labor-intensive and slow. It relies on skilled workers, careful formwork, and repeated cycles of packing and curing. This is where 3D printing enters the picture.

Large-scale construction printers can extrude earth-based mixtures layer by layer, effectively automating the ramming process. Instead of manual compaction inside temporary forms, robotic systems place material with precision and consistency. The result is faster construction, reduced labor costs, and greater design flexibility.

3D printing also allows architects to experiment with curved walls, variable thicknesses, and integrated features that would be difficult or expensive using conventional formwork. These design freedoms are particularly appealing for rammed earth, which already has a strong visual identity through its layered textures and natural color variations.

Architects Are Embracing Earth Again

The renewed interest in rammed earth is not driven by nostalgia alone. As Fast Company reports, architects are increasingly drawn to earth-based construction because it aligns with climate-conscious design goals. Rammed earth walls provide natural insulation and thermal stability, reducing reliance on mechanical heating and cooling systems.

The article highlights how modern rammed earth projects often blend traditional materials with contemporary engineering, creating buildings that meet current codes while significantly lowering carbon footprints. When paired with digital fabrication tools like 3D printing, these designs become more scalable and repeatable.

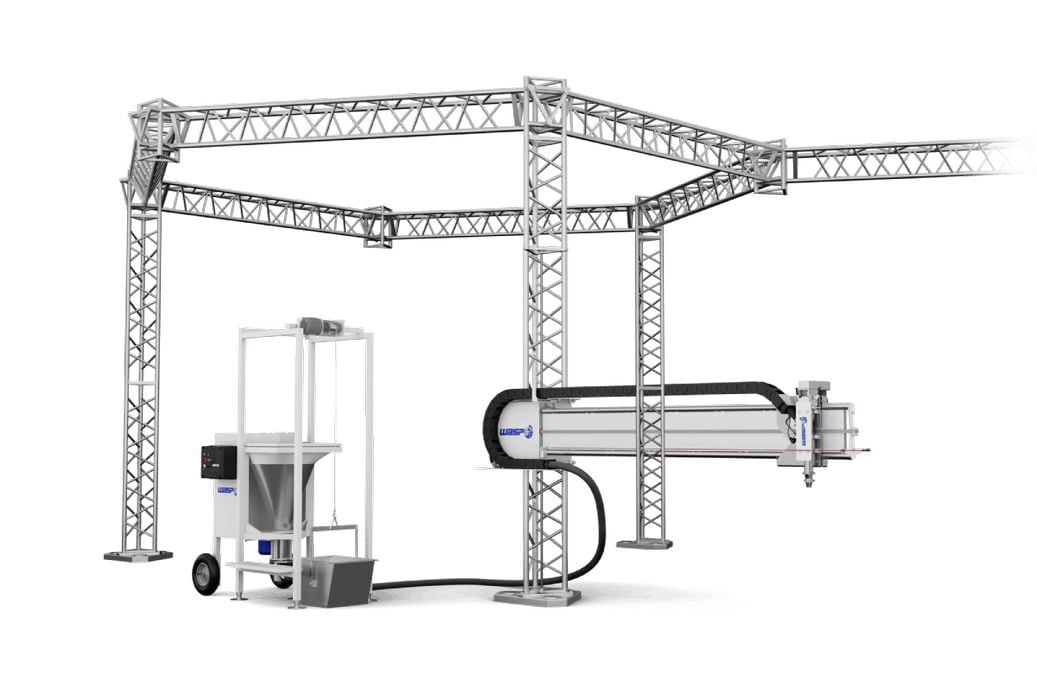

Crane WASP 3D printer [Source: WASP]

Crane WASP 3D printer [Source: WASP]

This shift reflects a broader movement within architecture toward materials that are regenerative, local, and adaptable. Earth is abundant, recyclable, and non-toxic. When used responsibly, it challenges the dominance of concrete and steel, which together account for a substantial share of global carbon emissions.

A Real-World Example: WASP’s Earth-Printed Homes

One of the most visible demonstrations of 3D printed earth construction comes from WASP, an Italian company known for pushing the boundaries of large-scale additive manufacturing. WASP has developed systems capable of printing homes using locally sourced soil, water, and natural binders.

In Japan, WASP showcased a 3D printed residential structure made primarily from earth-based materials. The project demonstrated how robotic printers can construct walls directly on-site, using regional soil compositions tailored for strength and durability. The resulting structure combined the visual warmth of rammed earth with the precision of digital fabrication.

What stands out in this project is not just the technology, but the philosophy behind it. By using earth from the building site or nearby locations, the construction process minimizes waste and transportation. The printer becomes a tool for translating local geology into livable architecture.

Environmental and Economic Benefits

The environmental case for 3D printed rammed earth homes is strong. Cement production alone is responsible for roughly 8 percent of global carbon dioxide emissions. Substituting earth-based materials for concrete in walls can dramatically reduce a building’s carbon footprint.

There are economic benefits as well. Automated construction reduces labor demands, which is particularly important in regions facing skilled labor shortages. Faster build times also translate into lower overall project costs, making housing more accessible.

Rammed earth structures are also durable and low-maintenance. Their resistance to fire, pests, and rot reduces long-term repair expenses. Over time, the initial investment can pay for itself through energy savings and longevity.

Design, Regulation, and Practical Challenges

Despite its promise, 3D printed rammed earth construction still faces hurdles. Building codes in many regions are written with concrete, steel, and wood in mind. Earth-based materials, especially when produced through novel methods like 3D printing, do not always fit neatly into existing regulatory frameworks.

Material consistency is another challenge. Soil composition varies widely from place to place, which can affect strength and printability. Successful projects require careful testing and sometimes the addition of stabilizers to meet structural requirements.

There is also a learning curve for architects, engineers, and contractors. Designing for additive manufacturing requires a different mindset, one that integrates material science, robotics, and architecture from the earliest stages of a project.

A Bridge Between Past and Future

What makes 3D printed rammed earth homes especially compelling is how they connect ancient building wisdom with modern technology. Humans have built with earth for thousands of years because it works. 3D printing does not replace that knowledge. It amplifies it.

By automating repetitive tasks and enabling precise control, digital fabrication allows earth construction to scale in ways that were previously impractical. This opens the door to broader adoption, from single-family homes to community housing and even disaster relief structures.

The layered walls produced by 3D printers echo the stratified look of traditional rammed earth, but with a distinctly contemporary character. These buildings do not hide their origins. They celebrate them.

The Research & Development Tax Credit

The now permanent Research & Development Tax Credit (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits

Looking Ahead

As climate pressures intensify and housing demands grow, the construction industry will need to rethink both materials and methods. 3D printed rammed earth homes offer a credible alternative that is rooted in sustainability, affordability, and resilience.

While challenges remain, the progress made by architects, researchers, and companies like WASP suggests that earth-based additive manufacturing is more than an experiment. It is a practical path forward to climate solutions and innovative construction strategies.

For an industry often criticized for slow change, this fusion of soil and software represents a meaningful step. By looking to the ground beneath our feet and the machines at our disposal, builders may finally find a way to construct homes that are as environmentally responsible as they are innovative dwelling structures.