Pritzker School of Engineering (Photo by Jason Smith) [Source: UChicago]

Pritzker School of Engineering (Photo by Jason Smith) [Source: UChicago]

Charles R. Goulding and Preeti Sulibhavi uncover the quantum leap between quantum science and 3D printing, which is expanding at the University of Chicago.

Quantum science is moving from theory to technology at a rapid clip, and 3D printing is becoming one of the tools that makes this shift possible. Across the world, researchers are learning that additive manufacturing can produce the highly intricate parts needed for quantum computers, quantum sensors, and integrated photonic circuits. At the same time, new ideas in qua…

Pritzker School of Engineering (Photo by Jason Smith) [Source: UChicago]

Pritzker School of Engineering (Photo by Jason Smith) [Source: UChicago]

Charles R. Goulding and Preeti Sulibhavi uncover the quantum leap between quantum science and 3D printing, which is expanding at the University of Chicago.

Quantum science is moving from theory to technology at a rapid clip, and 3D printing is becoming one of the tools that makes this shift possible. Across the world, researchers are learning that additive manufacturing can produce the highly intricate parts needed for quantum computers, quantum sensors, and integrated photonic circuits. At the same time, new ideas in quantum physics may reshape how we print materials at microscopic scales. The University of Chicago is deeply involved in this intersection. Through campus labs, cross-disciplinary research groups, and major investments in nanoscale fabrication, the university is helping shape the link between quantum and advanced manufacturing.

Why 3D Printing Matters for Quantum Research

Quantum devices rely on structures that are hard to produce with traditional machining. Ion traps, for example, need tiny electrode patterns arranged with precise geometry. Photonic chips require channels that guide light with accuracy at the micron scale. Quantum sensors depend on miniature cavities, lattices, and multi-material forms that support fragile quantum states. Even small errors can disrupt performance.

High-resolution 3D printing solves several of these engineering challenges.

First, it lets scientists build complex ion traps that support larger arrays of qubits. Conventional fabrication limits how quickly and flexibly these traps can be redesigned. With additive manufacturing, a researcher can change geometries in software, print a new design, test it, and repeat. This helps accelerate the move toward quantum computers with many more qubits.

Second, 3D printing makes quantum sensors smaller, lighter, and more integrated. Instead of assembling components one by one, engineers can print entire sensor platforms in a single structure. This may include optical elements, readout circuits, and mechanical supports. The result is a device that can be deployed more easily outside a research lab. Atomic clocks are an example. The more compact they become, the more they can be used in navigation, timing systems, and scientific fieldwork.

Third, additive manufacturing supports the creation of photonic components. In quantum information science, photons can serve as qubits or carry quantum information between nodes. Printing photonic chips or optical fiber structures offers a path to lower costs and faster production. It also supports experimental designs that would be too expensive or too delicate to manufacture by hand.

Finally, 3D printing opens the door to novel materials. Researchers have begun printing diamond structures that contain nitrogen vacancy centers, which are useful for quantum sensing. These centers respond to magnetic fields with a sensitivity that rivals other state-of-the-art techniques. Printing diamonds at small scales is difficult with traditional tools, but additive methods make it possible to grow the shapes required for specific sensor designs.

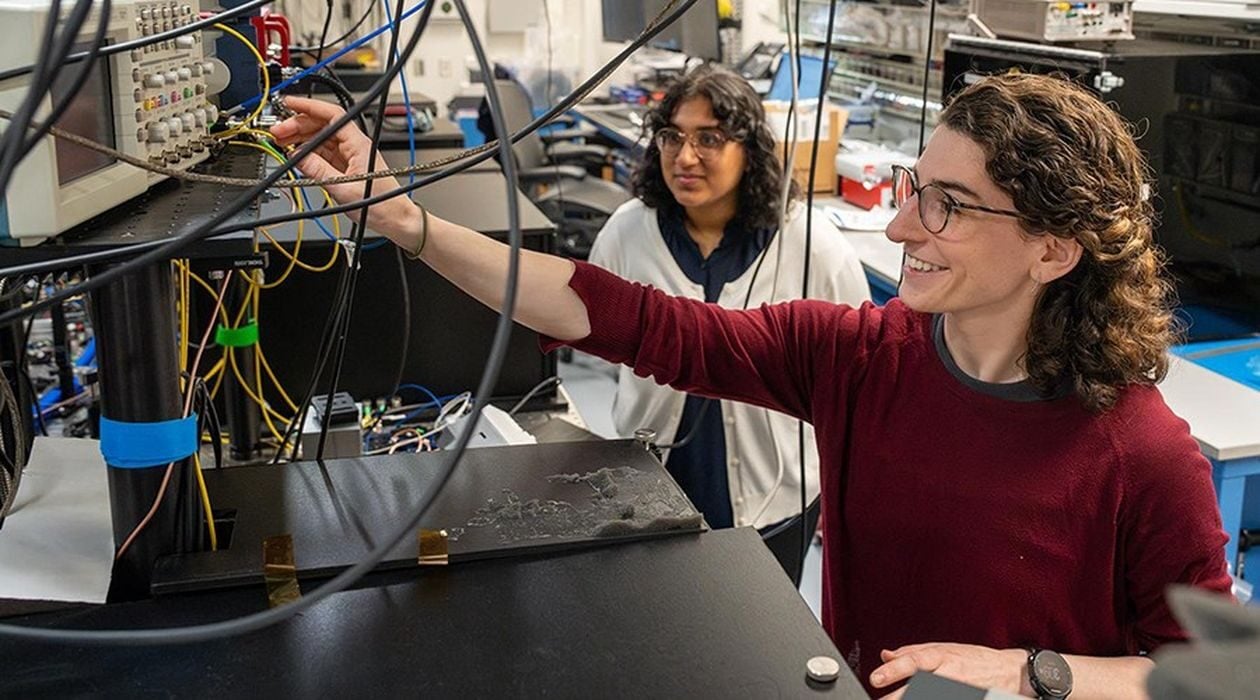

Graduate student Swathi Chandrika (left) and postdoctoral scholar Leah Weiss are part of the UChicago PME lab of Prof. David Awschalom, whose research group focuses on spintronics, solid-state and molecular quantum information science. (Photo by Jason Smith) [Source: UChicago]

Graduate student Swathi Chandrika (left) and postdoctoral scholar Leah Weiss are part of the UChicago PME lab of Prof. David Awschalom, whose research group focuses on spintronics, solid-state and molecular quantum information science. (Photo by Jason Smith) [Source: UChicago]

The Emerging Future: Quantum Principles Inside the Printer

Over the next decade, quantum physics may move from being the purpose of a printed device to being part of the printing process itself. Though still conceptual, researchers are imagining printers that manipulate matter with quantum-level control. Instead of depositing droplets or melted filaments, such printers might place individual atoms or molecules with precision.

This idea is sometimes called quantum 3D printing. It aims to reach a level of accuracy that produces structures impossible to make by ordinary means. If successful, it could change how we manufacture microelectronics and semiconductors, photonic circuits, and quantum hardware.

There is also speculation about quantum entanglement as a future tool for fabrication. In theory, entangled particles could allow real-time adjustments to a printed object based on feedback from its environment. Though speculative, this concept represents the type of long-term thinking that is common across quantum engineering.

While these ideas sit in the future, the work happening today sets the stage. By making quantum hardware easier to build and iterate on, 3D printing lowers barriers and speeds up discovery. This helps the whole research ecosystem grow.

How the University of Chicago Builds on These Trends with IonQ

The University of Chicago has become a leader in both quantum science and advanced fabrication. Its role is not limited to a single lab. Instead, it is spread across the campus through a network of facilities that combine creativity, engineering, and research.

The University of Chicago has struck a landmark agreement with IonQ to launch a cutting-edge quantum research initiative, placing a production-grade trapped-ion quantum computer and entanglement-distribution quantum network directly on campus. This deal is foundational: IonQ will deploy its next-generation quantum hardware at UChicago, while also backing a sponsored research program at the Pritzker School of Molecular Engineering. In tandem, the university will construct a new building named the IonQ Center for Engineering and Science, which will house UChicago’s advanced science and engineering research areas and deepen the collaboration between academic researchers and IonQ’s development teams.

Through this partnership, both UChicago and IonQ aim to accelerate discovery in multiple quantum domains — computing, networking, sensing, and security. UChicago brings a top-tier faculty, its Chicago Quantum Institute, and its affiliation with the Chicago Quantum Exchange (CQE), while IonQ contributes its real-world, commercial ion-trap systems. Together, their collaboration will support research across more than 140 potential projects, generate intellectual property for IonQ’s product roadmap, and bolster the quantum ecosystem in Chicago as IonQ becomes a core partner in the CQE.At the student and teaching level, the Hack Arts Lab supports 3D printing for creative projects, media studies, and coursework. It gives students access to printers, laser cutters, and fabrication tools through a simple enrollment process. This makes 3D printing part of everyday academic life, not just specialized research.

The table below presents the increase in R&D spend for IonQ, a leader in the Quantum industry, over the past few years.

For engineering students, the Mechanical Design and Fabrication Laboratory in the Michelson Center for Physics offers a more technical setup. It has CAD workstations, resin printers, and equipment used for physics projects and prototype development. Undergraduates and graduate students use it to prepare components for experiments, including those tied to quantum research led by faculty in the physical sciences.

The Pritzker School of Molecular Engineering (PME) pushes into deeper research territory. PME hosts advanced nanoscale 3D printers that work with vaporized precursors. These printers can create structures far smaller than the width of a strand of hair. This capability matters for microelectronics and for quantum technologies that require custom features at the nanoscale. One ongoing PME project centers on a direct-write nanoscale printer that earned recognition through an IBM PhD Fellowship. This work supports the development of new fabrication strategies that may eventually apply to quantum devices.

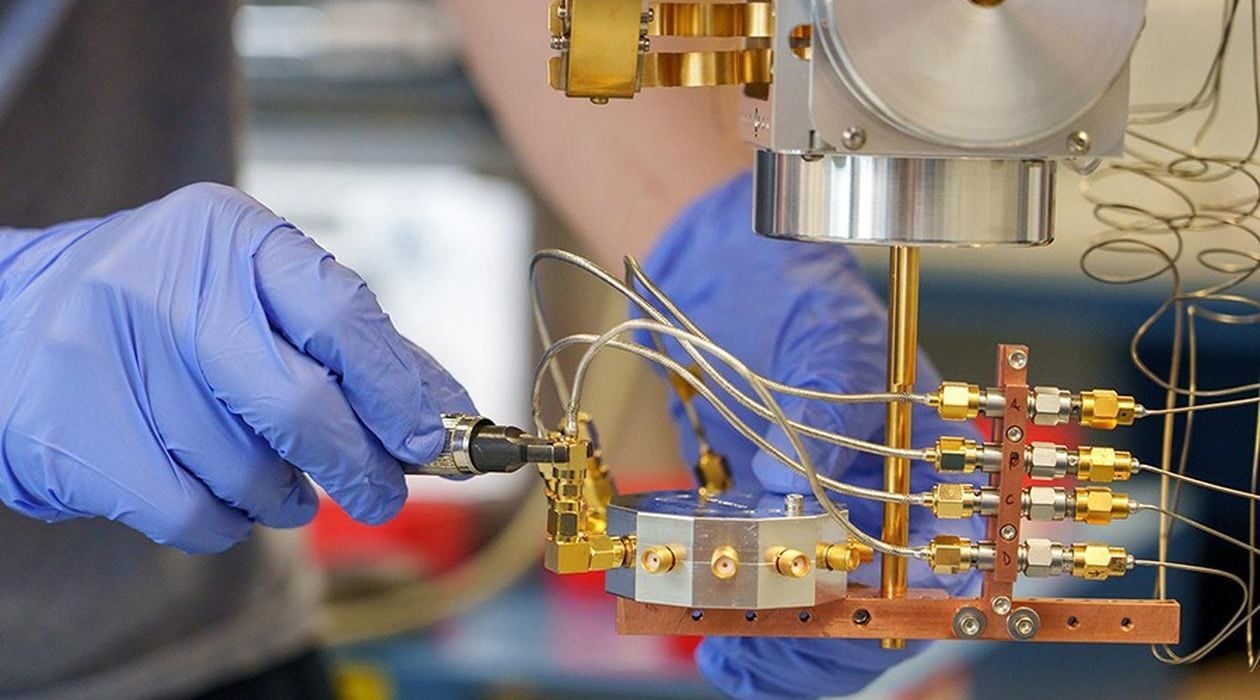

A researcher works on a quantum device in the lab of Prof. Andrew Cleland. (Photo by Joel Wintermantle) [Source: UChicago]

A researcher works on a quantum device in the lab of Prof. Andrew Cleland. (Photo by Joel Wintermantle) [Source: UChicago]

Robotics, Custom Fabrication, and Cross-Disciplinary Innovation

Several University of Chicago groups bolster the connection between robotics and additive manufacturing. The FabRobotics team, a collaboration with MIT, explores how mobile robots can support the printing process. These robots help produce larger objects, improve accuracy, and reduce waste. While not focused exclusively on quantum hardware, the techniques developed here can transfer to it. Precision robotics combined with high-resolution 3D printing can support the kind of complex architectures that quantum systems often need.

Beyond quantum science, University of Chicago researchers also push 3D printing into other fields. The Ota Lab works on tissue-engineered heart patches using bioprinting techniques. While this research addresses medical challenges, the core printing principles link back to the same set of capabilities that support quantum fabrication: precise deposition, multi-material integration, and the ability to build complex structures.

A recent grant to establish a 3D chip design hub at the university reflects a broader strategic focus. As chip architectures become three-dimensional, they require new fabrication methods. Quantum computing, microelectronics, and sensing can all benefit from this shift. This hub supports students and faculty in producing prototypes, testing designs, and advancing research in semiconductor and quantum technologies.

How Students and Researchers Can Get Involved

Students interested in creative or design projects can begin by enrolling in the Hack Arts Lab Canvas course. This provides training and access to the lab. Those working on physics, engineering, or research projects can visit the Mechanical Design and Fabrication Laboratory or speak with faculty in the Michelson Center for Physics. Researchers who need nanoscale printing capabilities or advanced fabrication methods can contact PME directly. For work that blends engineering, art, and media, the Logan Center for the Arts offers equipment and technical guidance.

The Research and Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes, and/or software. 3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D-printed prototypes can be included as a percentage of the eligible time spent on the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Graduate student Zixi Li, working in the lab of UChicago PME Prof. Alex High, is developing scalable hardware for quantum networking. (Photo by John Zich) [Source: UChicago]

Graduate student Zixi Li, working in the lab of UChicago PME Prof. Alex High, is developing scalable hardware for quantum networking. (Photo by John Zich) [Source: UChicago]

A Quantum Leap?

The connection between quantum science and 3D printing is expanding. University of Chicago’s combination of academic resources, research expertise, and interdisciplinary labs places it at the center of this growth. By combining quantum research with the flexibility of additive manufacturing, the university helps create tools that support the next generation of quantum technologies. As the field evolves, 3D printing will continue to play a central role, and the University of Chicago is positioned to shape that future.