TVAM combines volumetric and two photon 3D printing [Source: ArXiv]

TVAM combines volumetric and two photon 3D printing [Source: ArXiv]

Researchers unveiled a single machine that merges tomographic volumetric additive manufacturing with two photon polymerization to create true multiscale 3D prints in one coordinated workflow.

Why Combine Volumetric And Two-Photon?

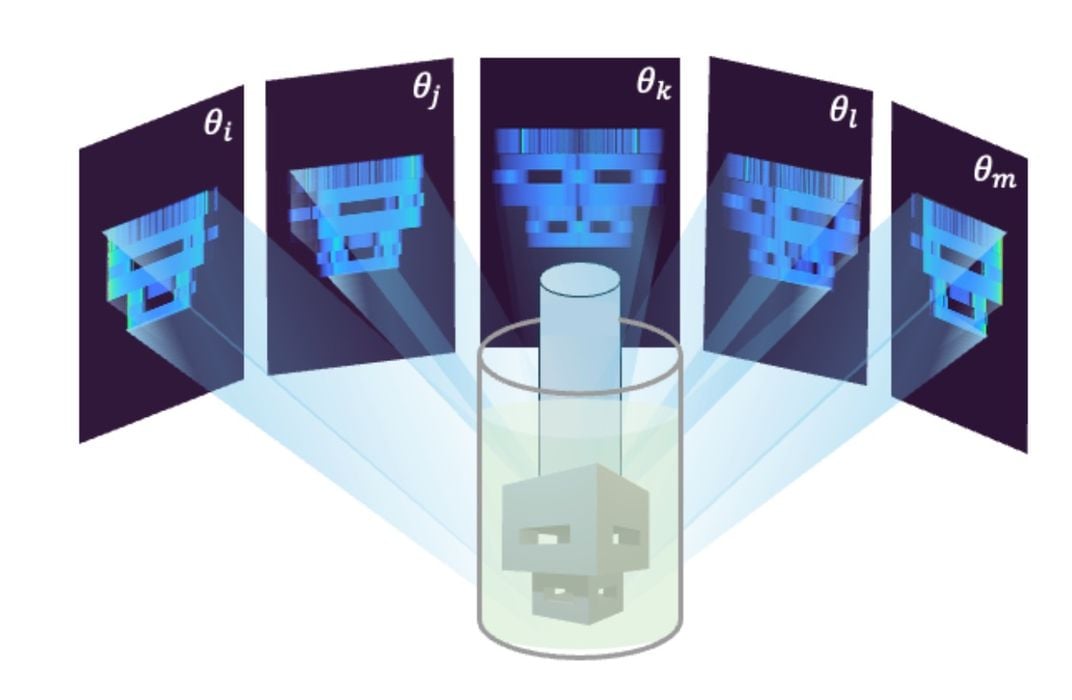

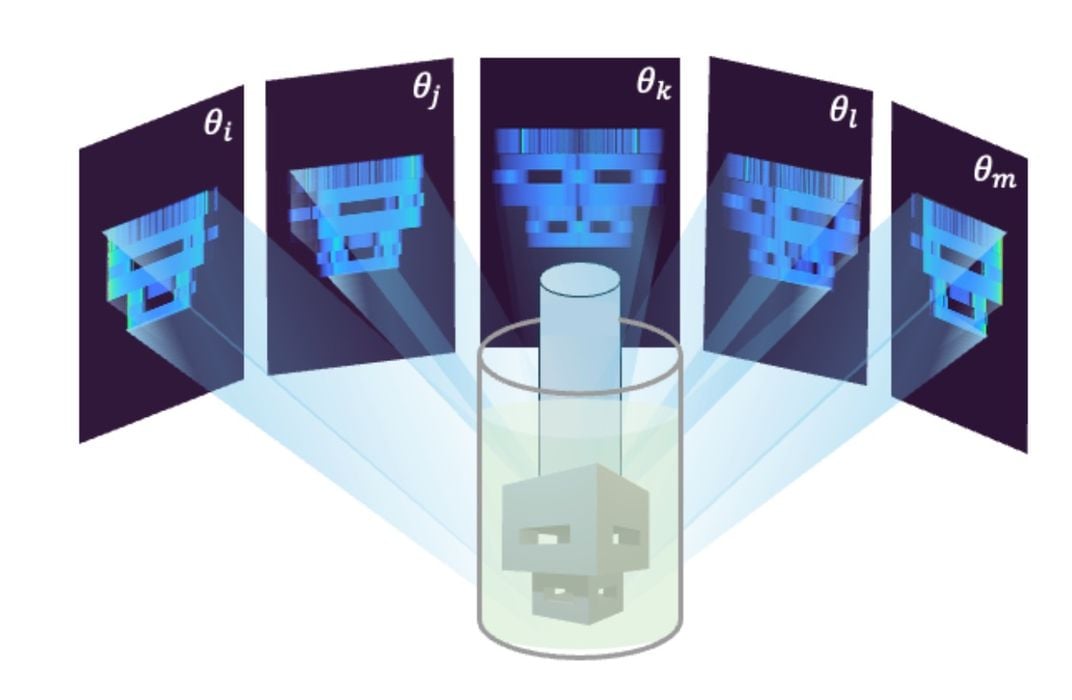

Tomographic Volumetric Additive Manufacturing (TVAM) uses projected light fields in a rotating or otherwise scanned vat to cure a full 3D shape in seconds to minutes through single photon absorption. It excels at speed, gentle handling, and support free fabrication of complex geometries, with several startups such as Readily3D and xolo commercializing variation…

TVAM combines volumetric and two photon 3D printing [Source: ArXiv]

TVAM combines volumetric and two photon 3D printing [Source: ArXiv]

Researchers unveiled a single machine that merges tomographic volumetric additive manufacturing with two photon polymerization to create true multiscale 3D prints in one coordinated workflow.

Why Combine Volumetric And Two-Photon?

Tomographic Volumetric Additive Manufacturing (TVAM) uses projected light fields in a rotating or otherwise scanned vat to cure a full 3D shape in seconds to minutes through single photon absorption. It excels at speed, gentle handling, and support free fabrication of complex geometries, with several startups such as Readily3D and xolo commercializing variations of the approach. The tradeoff is resolution: volumetric systems typically achieve meso scale features rather than microscale details.

Two-Photon Polymerization (TPP) is the opposite end of the spectrum. A tightly focused femtosecond laser induces non linear absorption only at the focal point, writing features down to hundreds of nanometers with superb fidelity. Systems from vendors like Nanoscribe set the benchmark for microfabrication, but voxel by voxel scanning limits throughput and practical build volume.

Uniting TVAM and TPP could deliver rapid bulk shaping with volumetric exposures, then add or refine critical microfeatures using TPP — all within the same resin, coordinate frame, and machine. That would reduce overall cycle times while preserving micro scale precision where it matters.

How A Unified Multiscale Platform Might Work

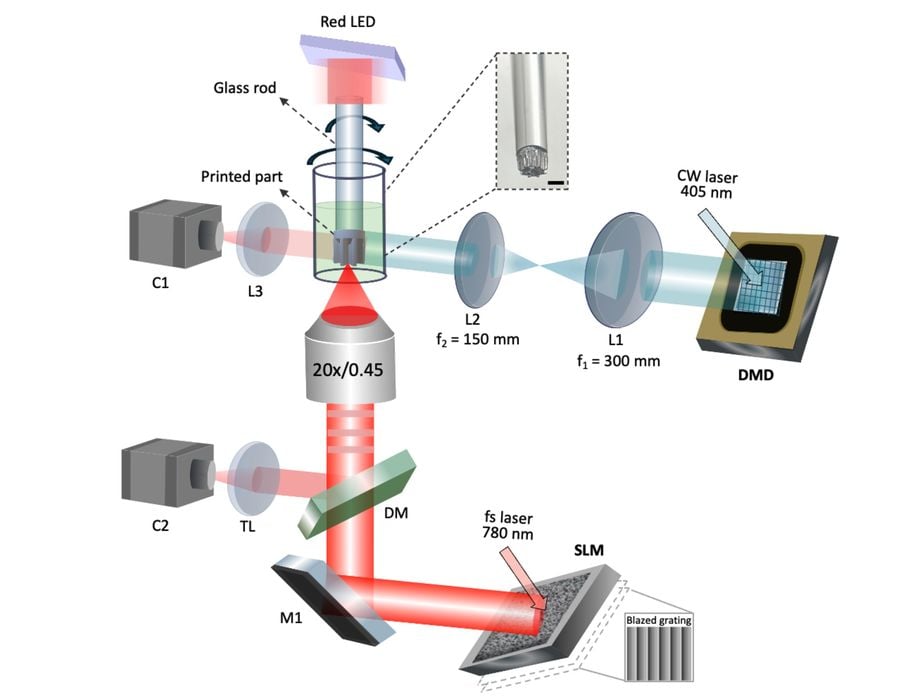

TVAM 3D printing test setup [Source: ArXiv]

TVAM 3D printing test setup [Source: ArXiv]

The paper describes a unified optical platform that combines single photon tomographic projections and a steerable, high numerical aperture TPP beam path. The machine first “sculpts” the part volumetrically to establish the macro and meso geometry, then switches to a tightly focused laser to draw microchannels, lattices, or surface textures in targeted zones.

The key enabler is likely a resin formulation compatible with both processes. TVAM typically relies on standard photoinitiators triggered by visible or near UV light, while TPP favors initiators with strong two photon cross sections at specific infrared wavelengths. A plausible solution is a dual initiator cocktail and spectral separation of the exposure paths. The authors do not disclose the full chemistry in the abstract, but the approach tracks with recent research.

Registration between modes is another challenge. For multiscale parts to be useful, the TPP features must land within tens of microns (or better) of the volumetric geometry. The system appears to share a common coordinate system and may rely on in situ imaging fiducials, tomographic reconstructions, or galvanometer calibration to stitch the two processes. The paper mentions unification in one machine, which should eliminate cross system alignment drift and human touch time.

This is primarily a research prototype, so specs such as build volume, volumetric exposure time, TPP writing speed, and minimum feature size are not provided in the paper. Based on known state of the art, expect volumetric builds in the centimeter class and TPP features from sub micron to a few microns, with scan speeds that are acceptable when confined to small regions. Post curing, resin handling, and oxygen inhibition constraints still apply, as with any photopolymer workflow.

Implications For Throughput And Applications

What is new here is not a faster TPP tool or a sharper volumetric printer, but the orchestration of both in the same job. That can change economics where only a fraction of a part demands micro scale detail. Microfluidic manifolds with macroscale bodies, optical connectors with precision interfaces, soft robotic actuators with integrated microchannels, and biomedical scaffolds with hierarchical porosity all fit this model.

Service bureaus and research labs could benefit first, since they already manage complex resin and optics workflows. For production, the gating factors will be material robustness, software to segment CAD into volumetric and TPP toolpaths, and demonstrated repeatability over many builds. If the resin compromises too much to serve both modes, mechanical properties or TPP contrast may suffer. Thermal management, aberration control, and vat transparency at two wavelengths are further engineering constraints.

Proof points to watch include quantitative registration accuracy between modes, surface roughness after the TVAM phase, the fraction of build time spent in TPP, and whether the team can show cross sectional micrographs of clean interfaces. A materials roadmap would also help, since the current formulation likely targets a narrow photopolymer class.

If follow on work validates reliability and publishes open benchmarks, this hybrid could become the reference architecture for multiscale photopolymer AM. Until then, it is an elegant answer to a question many have asked: how do we get speed and resolution without two separate machines?

ViaArXiv

By Kerry Stevenson

Kerry Stevenson, aka "General Fabb" has written over 8,000 stories on 3D printing at Fabbaloo since he launched the venture in 2007, with an intention to promote and grow the incredible technology of 3D printing across the world. So far, it seems to be working!

View all of Kerry Stevenson’s posts.