Step 1: Conceptual Design

The conceptual design phase sets the foundation of any project. Engineers define requirements, explore feasibility, and brainstorm potential solutions. Traditionally, this involves sketches, reviews, and discussions, which are often subjective and time-consuming.

How AI Helps

Artificial intelligence in mechanical engineering accelerates this stage by generating multiple design concepts based on defined parameters like weight, cost, and strength. Generative AI explores wide design spaces and suggests innovative shapes inspired by nature. Early AI simulations also eliminate weak ideas, reducing iteration cycles by up to 50%.

In addition, NLP tools analyze past project data, standards, and customer feedback. They identify requirement conflicts a…

Step 1: Conceptual Design

The conceptual design phase sets the foundation of any project. Engineers define requirements, explore feasibility, and brainstorm potential solutions. Traditionally, this involves sketches, reviews, and discussions, which are often subjective and time-consuming.

How AI Helps

Artificial intelligence in mechanical engineering accelerates this stage by generating multiple design concepts based on defined parameters like weight, cost, and strength. Generative AI explores wide design spaces and suggests innovative shapes inspired by nature. Early AI simulations also eliminate weak ideas, reducing iteration cycles by up to 50%.

In addition, NLP tools analyze past project data, standards, and customer feedback. They identify requirement conflicts and predict future needs, ensuring alignment with market demands.

Relevant Tools

- Autodesk Generative Design: Integrated into Fusion 360, this tool uses AI to create optimized designs by inputting goals like minimizing material use while maximizing durability. Ideal for lightweight components in aerospace.

- Leo AI: A generative AI copilot that transforms sketches or text descriptions into 3D models in seconds, trained on millions of CAD files. Perfect for rapid prototyping during brainstorming.

- Neural Concept Shape: Applies deep learning to generate and evaluate conceptual designs, particularly for fluid dynamics or structural elements, refining ideas before detailed modeling.

- Requirements Analysis: IBM Watson Discovery, Azure Cognitive Services for Language, Custom NLP pipelines (Python, spaCy, NLTK).

- Other Tools: nTopology, Ansys Discovery, Siemens NX (Generative Design), PTC Creo Generative Design,IBM Watson Discovery, Azure Cognitive Services for Language, Custom NLP pipelines (Python, spaCy, NLTK).

Step 2: Detailed CAD Modelling

Once ideas are narrowed down, engineers create detailed CAD models. This step defines dimensions, materials, and tolerances. Iterative refinements ensure accuracy, but the process can be repetitive and time-intensive.

How AI Helps

Here, AI in mechanical engineering reduces effort by automating tasks like dimensioning and compliance checks. Machine learning predicts how small changes affect the overall system. Generative design tools also create optimized variations that improve performance or reduce part counts.

This makes CAD work faster, more accurate, and more innovative.

Relevant Tools

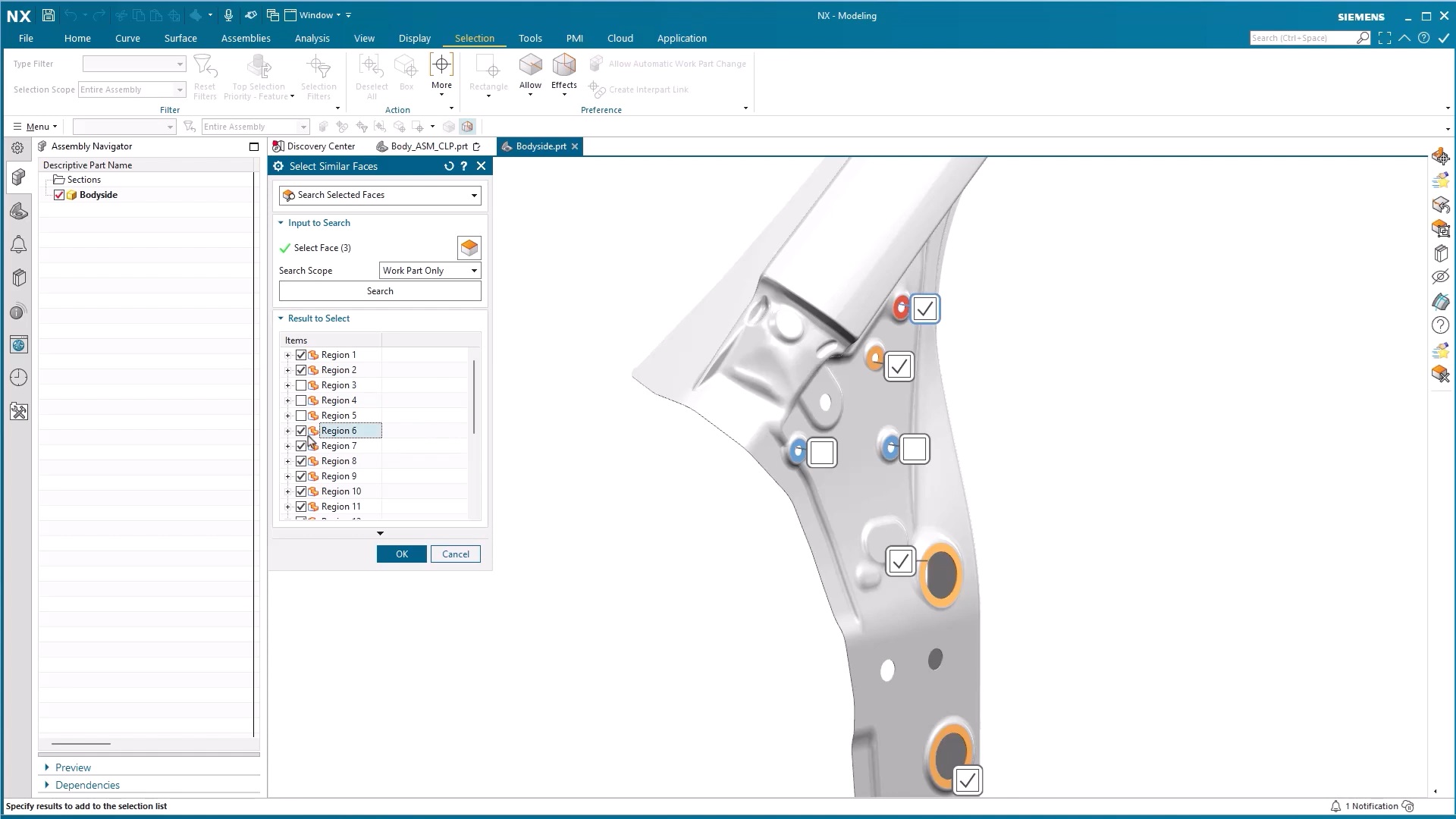

- Siemens NX: Features AI for automated design modifications and real-time collaboration, ideal for complex assemblies in mechanical systems.

- PTC Creo: Uses AI to optimize components for performance and manufacturability, suggesting fillet radii or material substitutions during modeling.

- Altair Inspire: AI-powered topology optimization tool that refines designs for structural integrity, commonly used in automotive chassis development.

- Generative Design: Autodesk Fusion 360 (Generative Design Extension), nTopology, Ansys Discovery,

- Other Tools: Dassault Systèmes 3DEXPERIENCE Platform AI features, Autodesk Fusion 360 (AI suggestions), 3DCS Variation Analyst, CETOL 6σ (Siemens).+ ThingWorx AI,

Sketch of a model [Ref]

Modeling in NX [Ref]

Step 3: Simulation and CAE Analysis

Simulation allows engineers to test designs virtually before physical prototypes. Using FEA, CFD, or thermal analysis, they predict real-world performance under stress, heat, or airflow. However, traditional simulations are computationally expensive and time-consuming.

How AI Helps

Artificial intelligence in mechanical engineering speeds up simulations with surrogate models that approximate results in minutes. AI also analyzes past simulations to forecast failures and optimize performance parameters. For instance, it can predict stress distribution in bridges or airflow in vehicles, reducing the need for physical prototypes.

Relevant Tools

- Ansys AI: Integrates AI for faster multiphysics simulations, enabling rapid exploration of “what-if” scenarios.

- SimScale: Cloud-based platform with AI-enhanced CFD and FEA, allowing real-time analysis without high-end hardware.

- Neural Concept: Uses deep learning for 3D shape optimization in simulations, predicting aerodynamic performance for vehicles or aircraft.

- Automated Meshing: SimAI (Ansys), Pointwise Glyph Scripting + ML integrations.

- Other Tools: Siemens Simcenter Reduced Order Modeling (ROM), Altair HyperWorks (AI-driven design exploration), Monolith AI, SimAI (Ansys), Pointwise Glyph Scripting + ML integrations, Monolith AI.

Fluid Flow Simulation [Ref]

Step 4: Prototyping

Prototyping validates ideas using physical or virtual models. While essential, this step can be expensive and time-consuming.

How AI Helps

AI in mechanical engineering optimizes prototyping by predicting material behaviors and reducing trial-and-error. Generative design produces stronger, lighter parts. In additive manufacturing, AI ensures precision layer by layer. Virtual prototyping also helps detect design issues early, saving costs before physical production.

Relevant Tools

- Autodesk Fusion 360 with AI: Extends generative design to prototype optimization, integrating with 3D printers for seamless fabrication.

- Leo AI: Generates prototype-ready CAD models from concepts, accelerating the transition to physical testing.

- Additive Manufacturing: Ansys Additive Suite (AI-powered process simulation),

- Predictive Tolerancing: 3DCS Variation Analyst (integrates with major CAD), CETOL 6σ (Siemens).

Using AI for prototype modeling [Ref]

Step 5: Manufacturing

Manufacturing scales prototypes into mass production. Efficiency, resource optimization, and quality are key challenges.

How AI Helps

Artificial intelligence in mechanical engineering is transforming manufacturing through smart factories, robotics, and digital twins. These virtual replicas monitor and adjust production in real time, improving efficiency and reducing errors. Predictive analytics also forecast equipment needs, which minimizes downtime and lowers maintenance costs.

AI-driven CAM (Computer-Aided Manufacturing) optimizes CNC toolpaths to reduce machining time, tool wear, and energy use. This improves surface finish and ensures collision avoidance during machining. Machine learning also predicts optimal feeds, speeds, and cutting strategies.

In process selection and feasibility, AI in mechanical engineering analyzes part geometry, material, quantity, and cost targets. It recommends the best manufacturing methods while detecting potential design-for-manufacturing (DFM/A) issues early.

Predictive process planning forecasts production times, resource requirements, and potential bottlenecks by analyzing historical data and current orders. In additive manufacturing, AI further optimizes build orientation, support structure generation, and process parameters—such as laser power and scan speed. This minimizes defects, distortion, and build time.

The result is a manufacturing process that is faster, more cost-effective, and more sustainable.

Relevant Tools

- Siemens Digital Industries Software: AI for factory automation, including predictive scheduling and robotics integration.

- PTC Creo Manufacturing Extensions: AI-optimized toolpaths for CNC and additive manufacturing, ensuring high-quality output.

- Process Selection/DFM: aPriori, Geometric DFMPro, Siemens Opcenter DFM Analyzer.

- CAM Optimization: Siemens NX CAM AI capabilities, Autodesk PowerMill (Machine Learning strategies), CELOS by DMG MORI (AI for machine tools), CloudNC.

- Predictive Planning: Siemens Opcenter APS (Advanced Planning & Scheduling) with AI, Oracle SCM Cloud AI features.

- AM Optimization: Ansys Additive Suite (AI-powered process simulation), Materialise Magics (AI support generation), 3D Systems Additive Manufacturing AI tools, GE Additive Amp.

Step 6: Quality Control and Testing

Quality checks confirm that manufactured products meet specifications. Manual inspections are often inconsistent and slow.

How AI Helps

Artificial intelligence in mechanical engineering brings a new level of precision to quality control. AI-powered computer vision systems detect defects with superhuman accuracy by analyzing images or sensor data in real time. These systems automatically identify surface issues such as scratches, dents, and porosity, as well as dimensional deviations and assembly errors, all at speeds far beyond human capability.

Machine learning models learn from historical inspection data and use it to flag anomalies more reliably. This reduces false positives, improves classification, and significantly speeds up inspections. In modern assembly lines, AI in mechanical engineering integrates with IoT devices for continuous monitoring. As a result, overall quality improves by 15–25%, with fewer errors reaching customers.

Relevant Tools

- IBM Maximo Visual Inspection: AI for defect detection in mechanical parts using image recognition.

- Automated Visual Inspection: Cognex ViDi, Keyence CV-X/AI Series, Landing AI, Matrox Imaging Library + Custom CV models (TensorFlow, PyTorch).

- Process Control: Rockwell Automation FactoryTalk Analytics, Siemens Edge solutions, Custom ML deployments.

- AI SPC: Seeq, Trendminer, Dataiku, Domino Data Lab.

Step 7: Maintenance and Lifecycle Management

Even after deployment, equipment requires ongoing care. Traditional reactive maintenance leads to high costs and downtime.

How AI Helps

Artificial intelligence in mechanical engineering makes maintenance predictive. By analyzing sensor data, AI forecasts failures and schedules proactive interventions. Digital twins continuously monitor equipment, suggesting performance improvements across the lifecycle. This reduces downtime and boosts reliability.

Relevant Tools

- IBM Watson IoT: AI for predictive maintenance in mechanical systems, integrating with sensors for real-time alerts.

- Ansys Digital Twin: AI-driven virtual models for ongoing optimization and fault prediction.

- Predictive Maintenance: Siemens MindSphere, PTC ThingWorx, GE Predix, Uptake, Falkonry.

- Test Planning/Optimization: Siemens Simcenter HEEDS, Altair HyperStudy, Ansys optiSLang.

- Test Data Analysis: MathWorks MATLAB (Statistics & Machine Learning Toolbox), Python (Pandas, Scikit-learn, PyTorch/TensorFlow), TDM Systems (DIAdem).

- Predictive Life Modeling: Ansys Digital Twin Builder, GE Digital Twin, Siemens Predictive Analytics Services.

- Intelligent PLM: PTC Windchill + ThingWorx AI, Siemens Teamcenter AI Assistants, Dassault Systèmes 3DEXPERIENCE AI features.