Written on 2025-10-31

Problem statement

Swiss kids have extensive hands-on lessons in primary school (called TTG1), where they work on all kinds of handcraft projects – pottery, papercraft, sewing machine work2, and more.

My son’s latest project is the ubiquitous sports bag that virtually all Swiss kids use for gym class – a canvas pouch that closes by pulling on the shoulder straps.

One fault I found in that design is that it slides off kids’ shoulders fairly easily.

So I set out to fix that – with a bit of 3D printing.

This is wholly deserving of the quickie tag – it was a quick job…

Solution

You know the whole:

- Sketch

- Extrude

- Possibly fillet/chamfer

Fusion360 workflow?

Yeah...

Written on 2025-10-31

Problem statement

Swiss kids have extensive hands-on lessons in primary school (called TTG1), where they work on all kinds of handcraft projects – pottery, papercraft, sewing machine work2, and more.

My son’s latest project is the ubiquitous sports bag that virtually all Swiss kids use for gym class – a canvas pouch that closes by pulling on the shoulder straps.

One fault I found in that design is that it slides off kids’ shoulders fairly easily.

So I set out to fix that – with a bit of 3D printing.

This is wholly deserving of the quickie tag – it was a quick job…

Solution

You know the whole:

- Sketch

- Extrude

- Possibly fillet/chamfer

Fusion360 workflow?

Yeah. This was exactly that kind of job:

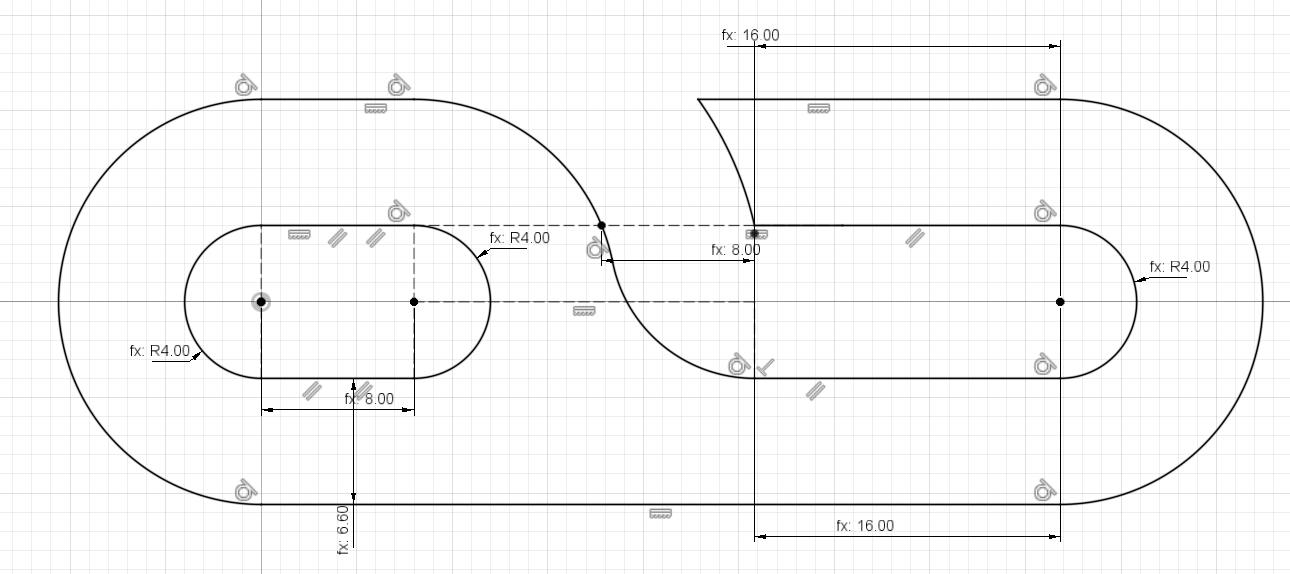

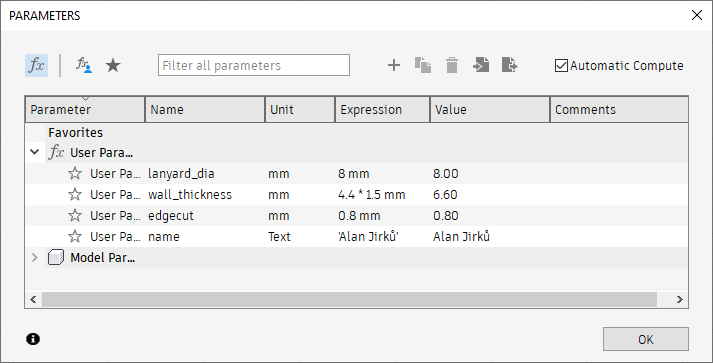

Sketch

Sketch the basic 2D shape

Sketch the basic 2D shape

(with some model params)

(with some model params)

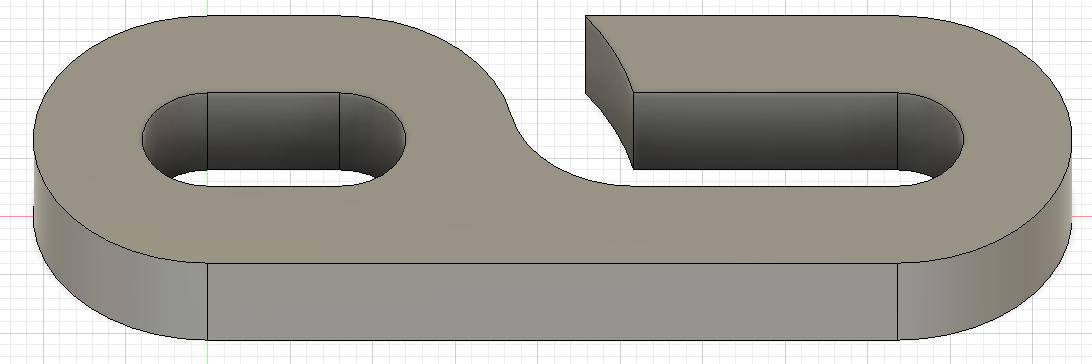

Extrude

Extrude the basic shape

Extrude the basic shape

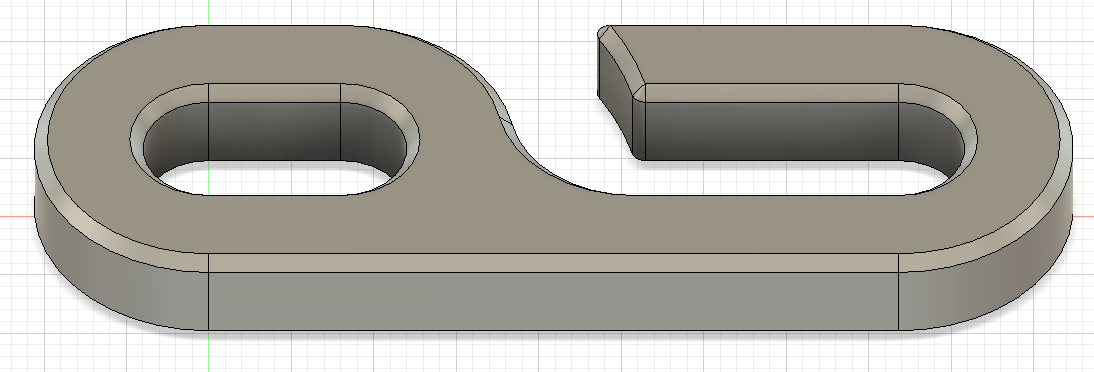

Fillet/chamfer

Fillet + chamfer (to cut sharp corners)

Fillet + chamfer (to cut sharp corners)

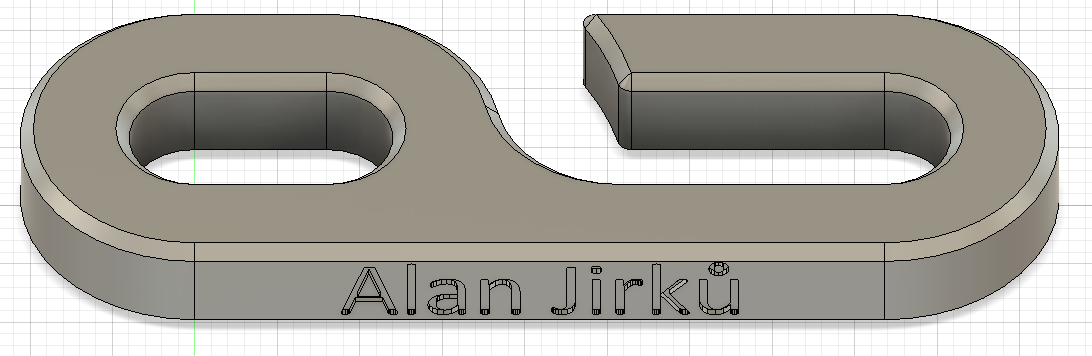

As a stretch goal, I added some personalization (an engraved name):

Finished model

Here’s the final result (sans the personalization, since you probably don’t want that):

[Right here should have been an interactive 3D model.]

The stl file as well as the f3d design file can be yours for the little price of free, under CC – BY NC SA license3.

Printing

It took two tries to get the dimensions just right (I designed the whole thing based on a rough measurement of the lanyard diameter), but the result turned out pretty cool, no?

The bag Alan sewed professionally, with the quick-hack clip I cobbled together in Fusion 360. ;)

Closing words

I don’t know – silly things like this remind me how much I enjoy living in a century where going from an idea to a finished “product” takes just a few keystrokes and a 30-minute wait4.

Textiles & Technisches Gestalten ↩ 1.

No kidding. They all (probably) sew better than I can. ↩ 1.

The non-commercial bit because I don’t want to get into hot water with Autodesk since my license is the free hobbyist one. Not that you could commercialize a trivial model like this… ↩ 1.

On my ancient Ultimaker 2+. I’m sure Prusa’s new would’ve done a much quicker job of it. Maybe even with better surface finish. ↩