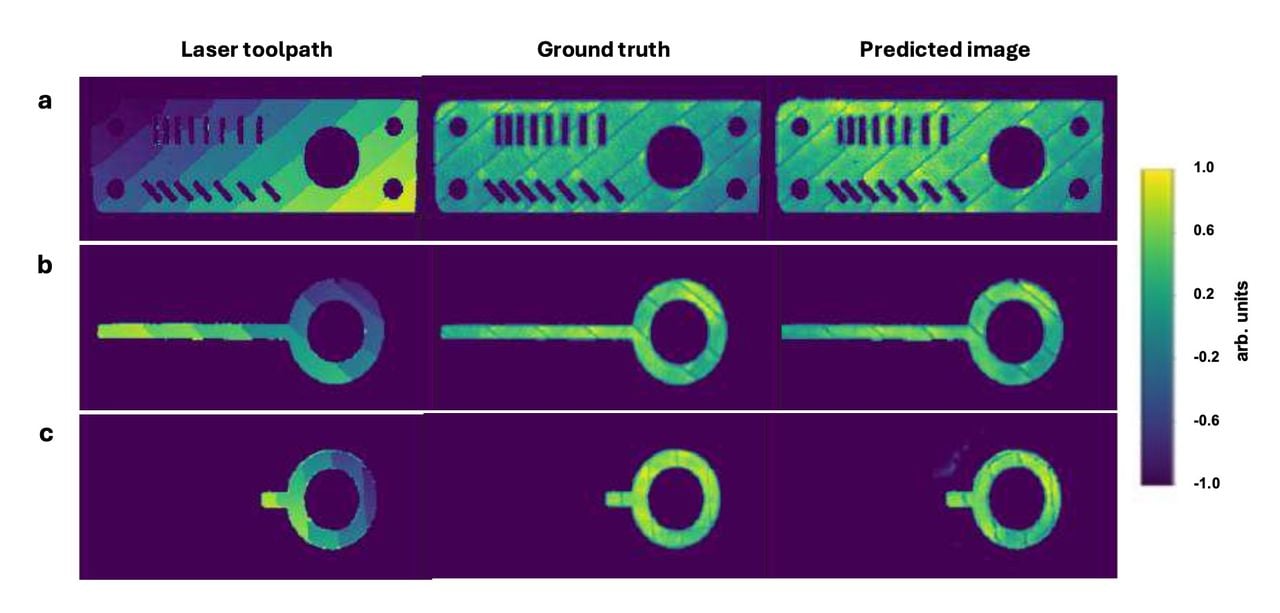

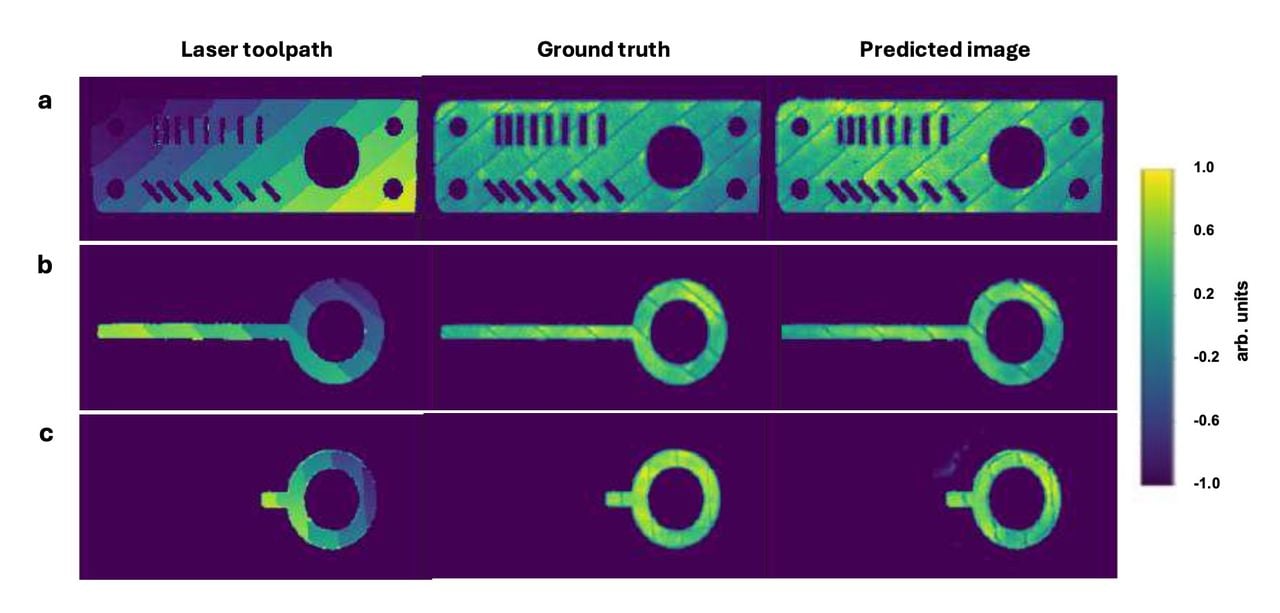

AdditiveGDL layer by layer prediction vs [Source: Research Square]

AdditiveGDL layer by layer prediction vs [Source: Research Square]

Researchers introduced AdditiveGDL, a generative deep learning method that predicts local thermal distributions across metal Laser Powder Bed Fusion layers to accelerate process tuning and quality assurance.

Why Thermal Prediction Matters In LPBF

In metal Laser Powder Bed Fusion (LPBF), thermal history is destiny. Local heat input and heat removal govern whether a track runs in conduction or keyhole mode, whether pores form, how residual stress accumulates, and which microstructures solidify. Predicting that thermal field at the layer level is the difference between a part that survives machining and certification and a part that crac…

AdditiveGDL layer by layer prediction vs [Source: Research Square]

AdditiveGDL layer by layer prediction vs [Source: Research Square]

Researchers introduced AdditiveGDL, a generative deep learning method that predicts local thermal distributions across metal Laser Powder Bed Fusion layers to accelerate process tuning and quality assurance.

Why Thermal Prediction Matters In LPBF

In metal Laser Powder Bed Fusion (LPBF), thermal history is destiny. Local heat input and heat removal govern whether a track runs in conduction or keyhole mode, whether pores form, how residual stress accumulates, and which microstructures solidify. Predicting that thermal field at the layer level is the difference between a part that survives machining and certification and a part that cracks on the plate.

Until now, industry has leaned on two imperfect options. High fidelity multiphysics simulation can resolve melt pool dynamics and cooling rates, but the compute burden scales brutally with build volume and small timesteps. It is powerful for research and a few critical zones, less so for production-scale sweeps. On the other side, in-situ monitoring — coaxial photodiodes, visible and IR cameras — captures rich signals but is primarily descriptive, and turning those signals into actionable control remains challenging. A fast, reliable surrogate that produces spatial temperature maps could bridge these worlds.

A Generative Shortcut To The Thermal Field

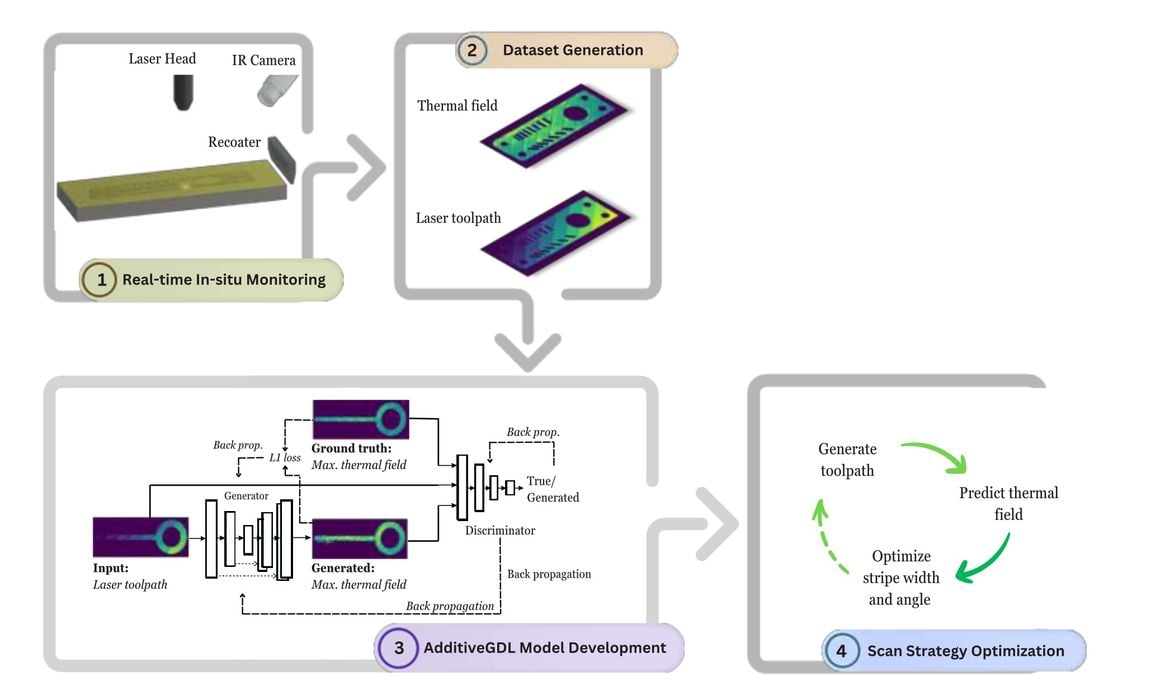

AdditiveGDL process [Source: Research Square]

AdditiveGDL process [Source: Research Square]

The AdditiveGDL paper proposes a generative deep learning approach focused on local thermal distributions within 3D printed layers. Rather than numerically solving energy equations, a trained model generates a temperature field conditioned on the layer context. In practice, such models typically ingest aspects of geometry and scan strategy and output a pixelwise thermal estimate, enabling rapid what-if analysis across scan parameters without hour-long simulations. The work is posted as a Research Square preprint, which means the text is public but not yet peer reviewed.

What is interesting here is the emphasis on local detail. AM engineers often talk about average interlayer heat accumulation, but failures tend to nucleate in specific neighborhoods — overhang edges, thin ribs, contour-to-hatch intersections, or multi-laser overlap zones. A generative network that reproduces those spatial variations, even approximately, could flag hot spots ahead of time, inform hatch spacing or power modulation, and reduce iterations. If inference runs near real time on a GPU, it could also serve as a viable component in a digital twin pipeline.

There are caveats. The authors do not, in the abstract and listing, spell out training corpus size, inference speed, or error metrics against thermography or high fidelity benchmarks. Generalization across alloys and machines is a recurring problem: emissivity changes, powder absorptivity, laser spot size, shielding gas flow and preheat all shift the thermal landscape. Multi-laser interactions and scan restarts introduce transients that are hard to learn without targeted data. Without uncertainty estimates, a generated map could look convincing while being off by a harmful margin.

Even with those constraints, the potential impact is clear. Service bureaus and OEMs could use a fast generative surrogate to prune process windows and concentrate expensive experiments where the model predicts risk. Software vendors could embed it upstream of toolpath generation to adapt scanning strategies around predicted hot or cold pockets. Quality teams could compare predicted fields against in-situ signals as a cross-check, improving trust in both monitoring and simulation. If paired with modest automation, this could cut human touch time in parameter development and reduce scrap on first-article builds.

The adoption path likely runs through calibration and coupling. Expect per-machine, per-material tuning or transfer learning, possibly using a small set of thermography layers to align the model. A credible route to closed loop control would fuse AdditiveGDL-like predictions with sensor feedback to nudge power or speed within a layer, bounded by OEM safety limits. Integration with established AM software — from scan-field generators to build simulation tools — will matter as much as raw model accuracy.

What to watch next: rigorous validation on representative geometries, published comparisons against finite element or finite volume baselines, and honest failure cases. If the team releases code or a dataset, community benchmarking could accelerate progress. Alternatively, a partnership with a machine OEM or a simulation vendor would signal a push toward productization and controller integration.

If generative models can reliably sketch tomorrow’s heat map today, metal AM may increase performance and part quality.

Via Research Square